Hello Woodsy! I was wondering why you hadn't published the third and final part of my Soft Vinyl adventures...

It was because I'd written it , but not sent it! So, without further ado...

(And Woodsy adds: I then went to Germany and forgot to do it! My bad! )

Having finally made a passable helmet, I used my learnings to produce a pretty decent soft vinyl hat mould.

However, getting suitable PVC Polyol proved to be a much bigger problem than expected. Australia still has a manufacturing capability with PVC moulders and material supplies actually existing. However they are uninterested in orders under the Tonne level, one actually hung up on me when I asked what a minimum order would be. Ultimately I made a $6K order through China and it wasn't ultimately very satisfying, but I digress.

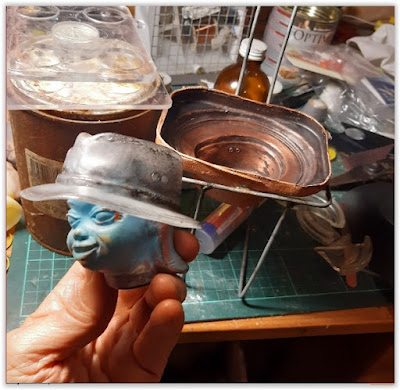

Here's a usable copper hat mould. The exterior coral textured surface is the best I could do, but it wasn't a problem as the inner working surface was smooth.

Back to the Oil Bath for a more pleasant cooking experience. I'm not including the photo of me in leather apron and arm shields and the positive pressure breathing mask I bought just to avoid breathing scorched Oil fumes!

Here's Besset's head and arm, moulded and cast in wax, with a copper powder polish to try and increase inner surface conductivity during the Electroforming process....

The finished arm mould with it's very necessary shoulder joint that caused no end of release problems at the cooking stage.

Most of the moulds, like this body piece never made it that far....

Ultimately, it was such a labour intensive project with such a high failure rate, that I ended up abandoning the entire idea ...until I decided to try 3D printing instead.

I still don't have that lovely flexible soft vinyl texture, but at least the technical details are no longer cramping my dreams and aspirations!

Looey

OZ Base

°

You can follow the entire agonizing process on my Instagram blog

Happy modelling, Moonbasers!

Product manufacturing is a whole different ball game to media prop making Looey.

ReplyDeleteI have a former colleage who tried it professionally in the early 2000s and he ended up getting a limited run of his models made in China.

You are a brave man, to keep at such a project. I am afraid that I will stay with my nice, simple plastic kits, and preserve my sanity. Good luck with the 3-D printing.

ReplyDeleteThis toy-making is pure artistry! Bravo! SFZ

ReplyDeleteThat was one heckuva project Looey! The results were well worth the efforts put into the undertaking.

ReplyDeleteIncredible effort Looey. You dipped your toe into the mystic for sure. Great set of posts. Thanks!

ReplyDelete